Introduction

In modern electrical infrastructure, safe and efficient cable management is fundamental to system reliability, compliance, and long-term performance. Among the most frequently misunderstood components in electrical installations are pull boxes and junction boxes. Although they may appear similar in form and material, their functional roles, design intent, and regulatory requirements differ substantially.

This article provides an in-depth, professional, and technically accurate comparison of Pull Box vs Junction Box, addressing design principles, applications, compliance standards, installation practices, advantages, limitations, and decision-making criteria. The content is developed for engineers, contractors, procurement specialists, and infrastructure planners, with a global perspective aligned to international electrical standards.

Lianjie Supply Chain, a China-based global sourcing platform operating in English, supports industries worldwide by providing access to compliant electrical enclosures, cable management solutions, and industrial components that meet international quality and performance expectations.

Understanding Electrical Enclosures in Power Distribution Systems

Electrical enclosures serve as protective and organizational components within wiring systems. Their primary objectives include:

- Protecting conductors from mechanical damage

- Ensuring safe access for maintenance

- Managing cable routing and transitions

- Supporting compliance with electrical codes

- Reducing fire and short-circuit risks

Two of the most common enclosure types are pull boxes and junction boxes. Despite overlapping physical characteristics, they are not interchangeable and must be selected based on function rather than appearance.

What Is a Pull Box?

Definition and Purpose

A pull box is an electrical enclosure designed specifically to facilitate the pulling, bending, or re-routing of conductors within a conduit system. It does not contain wire splices, terminations, or electrical connections.

Its primary role is mechanical rather than electrical.

Core Functions of a Pull Box

- Reduces cable pulling tension

- Allows directional changes in conduit runs

- Prevents conductor insulation damage

- Enables access during cable installation or replacement

- Supports long or complex conduit layouts

Pull boxes are particularly critical in installations involving large-gauge conductors, long conduit runs, or multiple directional changes.

Typical Applications of Pull Boxes

Pull boxes are commonly used in:

- Commercial buildings

- Industrial facilities

- Utility infrastructure

- High-rise construction

- Data centers

- Power substations

They are installed at calculated intervals to meet cable pulling limitations defined by electrical standards.

Structural Characteristics of Pull Boxes

- Large internal volume

- Smooth internal surfaces

- Minimal internal fittings

- Heavy-duty construction

- Designed for cable movement rather than connection

Pull boxes are often rectangular or square and may be wall-mounted, floor-mounted, or embedded in concrete.

Materials Used in Pull Boxes

- Galvanized steel

- Stainless steel

- Aluminum

- Fiberglass-reinforced polyester

- Heavy-duty thermoplastics

Material selection depends on environmental exposure, corrosion risk, and mechanical load requirements.

What Is a Junction Box?

Definition and Purpose

A junction box is an enclosure designed to house electrical connections, including splices, taps, and terminations. It serves as a controlled environment where conductors are electrically joined or distributed to multiple circuits.

Unlike pull boxes, junction boxes are electrically active components of the system.

Core Functions of a Junction Box

- Protects wire connections

- Contains splices and terminations

- Distributes power to branch circuits

- Provides access for inspection and maintenance

- Reduces fire and shock hazards

Junction boxes are essential in virtually all electrical installations.

Typical Applications of Junction Boxes

Junction boxes are used in:

- Residential wiring systems

- Commercial buildings

- Industrial control panels

- Lighting circuits

- HVAC systems

- Telecommunications and data cabling

They are installed wherever conductors are joined or split.

Structural Characteristics of Junction Boxes

- Compact internal space

- Mounting points for connectors

- Knockouts for cable entry

- Covers with secure fastening

- Often rated for indoor or outdoor use

Their design prioritizes connection safety and accessibility rather than cable movement.

Materials Used in Junction Boxes

- PVC and thermoplastics

- Die-cast aluminum

- Sheet steel

- Stainless steel

- Flame-retardant composites

Material selection is driven by voltage level, environmental exposure, and installation location.

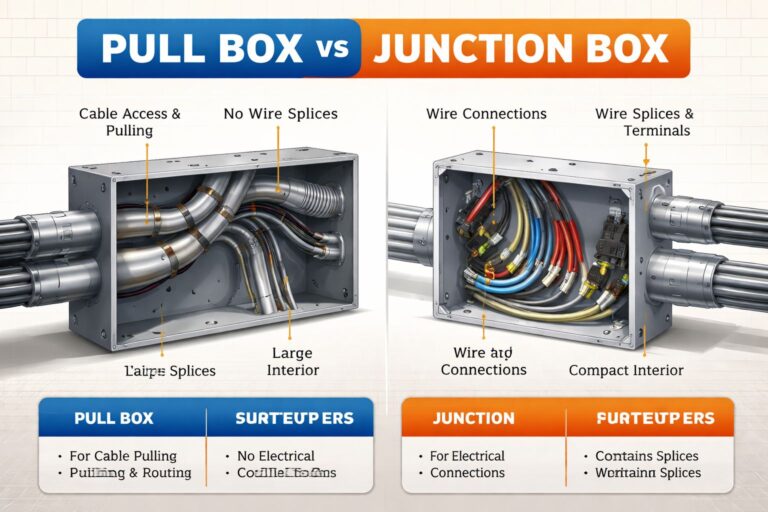

Pull Box vs Junction Box: Key Differences

Functional Difference

| Aspect | Pull Box | Junction Box |

|---|---|---|

| Primary Function | Cable pulling and routing | Wire connections and splicing |

| Electrical Connections | Not permitted | Required |

| Mechanical Role | High | Moderate |

| Electrical Role | None | High |

Design Intent

Pull boxes are designed to reduce mechanical stress, while junction boxes are designed to protect electrical joints.

Using one in place of the other violates electrical codes and compromises system safety.

Size and Capacity

Pull boxes are generally larger to allow conductor movement, whereas junction boxes are smaller and compact, optimized for connection density.

Internal Components

- Pull boxes: No terminals, no splices, no connectors

- Junction boxes: Wire nuts, terminal blocks, grounding points

Regulatory Compliance

Electrical standards strictly differentiate between pull boxes and junction boxes:

- Pull boxes must meet conduit fill and bending radius rules

- Junction boxes must meet splice accessibility and enclosure rating requirements

Failure to comply can lead to inspection failure or safety hazards.

Electrical Code Considerations

Pull Box Code Requirements

- Must allow sufficient space for conductor bending

- Must not contain splices

- Must remain accessible after installation

- Must comply with conduit size ratios

Junction Box Code Requirements

- All splices must be enclosed

- Must have removable covers

- Must remain accessible

- Must provide grounding continuity

Both enclosure types must be properly rated for voltage, environment, and application.

Environmental and Protection Ratings

Indoor Applications

- Standard steel or plastic enclosures

- Lower ingress protection ratings

Outdoor and Industrial Applications

- Weatherproof, dustproof, corrosion-resistant materials

- Higher ingress protection ratings

- UV resistance where applicable

Correct rating selection is critical for longevity and safety.

Installation Best Practices

Installing Pull Boxes

- Place at calculated intervals along conduit runs

- Ensure smooth conduit entry alignment

- Avoid sharp bends

- Maintain clear internal space

- Secure firmly to structural elements

Installing Junction Boxes

- Ensure adequate space for all conductors

- Use approved connectors and splices

- Maintain grounding continuity

- Label circuits where required

- Secure covers properly

Common Installation Mistakes

Pull Box Errors

- Installing splices inside pull boxes

- Using undersized enclosures

- Blocking access after construction

- Ignoring conduit bending rules

Junction Box Errors

- Overfilling with conductors

- Leaving exposed connections

- Using non-rated materials

- Installing in inaccessible locations

Such errors increase fire risk and system failure probability.

Cost Considerations

Pull boxes typically cost more due to:

- Larger size

- Heavier materials

- Structural reinforcement

Junction boxes are generally less expensive but are used in greater quantity.

Cost decisions should be based on functional necessity, not price alone.

Industrial and Commercial Use Cases

Pull Box Use Case Example

In an industrial facility with long conduit runs carrying high-current conductors, pull boxes reduce installation time, prevent cable damage, and support future maintenance.

Junction Box Use Case Example

In a commercial building lighting system, junction boxes safely distribute power to multiple fixtures while maintaining code compliance and serviceability.

Selecting the Right Enclosure

Choose a Pull Box When:

- Conductors are large or heavy

- Conduit runs are long

- Direction changes are required

- No splicing is needed

Choose a Junction Box When:

- Conductors must be connected or split

- Circuit distribution is required

- Electrical devices are connected

- Inspection access is necessary

The Role of Global Sourcing in Electrical Infrastructure

Lianjie Supply Chain operates as a China-based global sourcing platform, enabling international buyers to access high-quality electrical enclosures, including pull boxes and junction boxes, manufactured to meet global standards.

By sourcing through an English-language platform with international reach, procurement teams benefit from:

- Consistent quality control

- Material compliance

- Custom sizing options

- Scalable supply chains

- Competitive manufacturing advantages

Global sourcing plays a vital role in modern infrastructure development.

Future Trends in Electrical Enclosure Design

- Modular enclosure systems

- Enhanced corrosion-resistant materials

- Lightweight composite enclosures

- Smart access and monitoring features

- Increased compliance harmonization across regions

As electrical systems grow more complex, enclosure design continues to evolve to support safety, efficiency, and sustainability.

Conclusion

The comparison of Pull Box vs Junction Box highlights a fundamental principle of electrical system design: form must follow function.

Pull boxes exist to facilitate cable movement and protect conductors during installation and maintenance. Junction boxes exist to contain and protect electrical connections. Confusing or misusing these enclosures compromises safety, violates electrical codes, and increases long-term system risk.

Understanding their differences, applications, and compliance requirements ensures better system performance, reduced maintenance costs, and improved operational safety.

For professionals involved in design, construction, procurement, or maintenance, selecting the correct enclosure is not optional—it is a critical responsibility.